Toughened Glass

Additional Information

TOUGHENED GLASS

Toughened Glass, or Tempered Glass, is made by heating annealed glass at a temperature of approximately

650-700 °Celsius, when it starts to soften, a strong compression being created when the external surfaces are then rapidly cooled. The heating process, followed by the cooling one is controlled and the parameters used by this process have a fundamental influence on the quality of the toughened glass.

Therefore, it is more resistant to thermal breakage and is capable of withstanding higher wind loads. A fully toughened glass is 4 to 5 times stronger than an annealed glass of similar thickness. The full toughened glass is regarded as a safety glass and when it breaks it disintegrates into small blunt pieces which greatly reduces the chances of injuries.

HEAT STRENGTHENED GLASS

Heat strengthened glass is a semi toughened glass, which has been strengthened thermally by inducing a surface compression of 6000 to 9000 psi as compared to a range of 11000 to 20000 psi in case of fully toughened glass. It is two times stronger than annealed glass. Though it is not considered to be a safety glass, it is widely used on building facades due to better optics, especially in spandrel applications.

HEAT SOAK TESTING

Effective Heat-soak test has been proposed and applied for toughened glass to avoid spontaneous failure in

buildings, and the probability of spontaneous breakage was decreased. However, it was considered that a sufficiently low breakage risk was remained because of small NiS inclusion and small residual stress.

Heat soaking of tempering glass has carried out in respect to the draft of European Standard EN 14179.

Following the tempering process, glass is heated to a temperature of about 290C for a minimum of 2 hours of the heat-soak period, and then cooled slowly. This process allows the inclusions to revert to their original form and thus regain their stability. The advantage in using this process is that the heat-soak test removes over 95% of the problem without affecting the properties of the glass. The idea behind heat soaking is to allow the glass to break in the factory before installation to minimize the risks of accidents and injury. The amount and size of these inclusions vary from glass to glass. In all probability, the glasses that have NiS inclusions will break during this heat soaking process.

Get a Quote Here

To get a quote on your next Toughened Glass project, simply provide us your estimated quantity, sizes and types of toughened glass you're after and we will get right onto it!

If your unsure of any of the above, you can give us a call and we can help guide you through what you need.

Toughened Glass Specification

SPECIFICATION:

• Maximum Size: 3600 x 18000mm

• 4, 5, 6, 8, 10, 12, 15, 19, 22, 25mm glass thickness available

• available colors - clear, ultra clear, grey, bronze, blue, green and many custom colors are available

• You can make toughened glass into laminated, curved & insulated glass

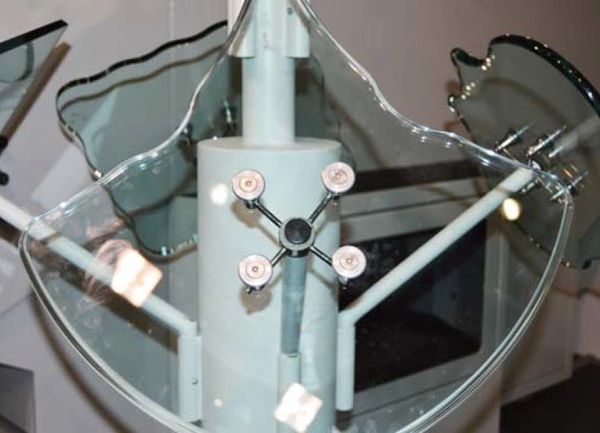

APPLICATIONS:

curtain walls, shopfronts, balustrades, skylights, sightseeing elevator, indoor glass partitions, office modules, frameless doors, squash courts, frameless shower screens, viewing walls, frameless glass enclosures

Photo Gallery

Video

Downloads

Files coming soon.